At TEC Aerospace, our fleet of advanced Haas CNC Machines forms the core of our manufacturing strategy, enabling us to produce mission-critical military components with unparalleled precision. In the defense industry, there is no room for error. Every part must perform flawlessly under extreme conditions, and our commitment to this standard begins on our shop floor with our strategic investment in American-made manufacturing technology.

Our milling operations are anchored by a versatile range of Haas machines, including the VF-2, VF-4, and the compact Mini-Mill. These powerful vertical machining centers allow us to tackle components with highly complex geometries, from structural airframe parts to intricate hydraulic manifolds. We work with advanced materials like titanium and high-strength alloys, which are essential for modern defense applications but notoriously difficult to machine . The rigidity and precision of our Haas mills ensure we can hold the tight tolerances, often down to sub-micron levels, that our military clients demand.

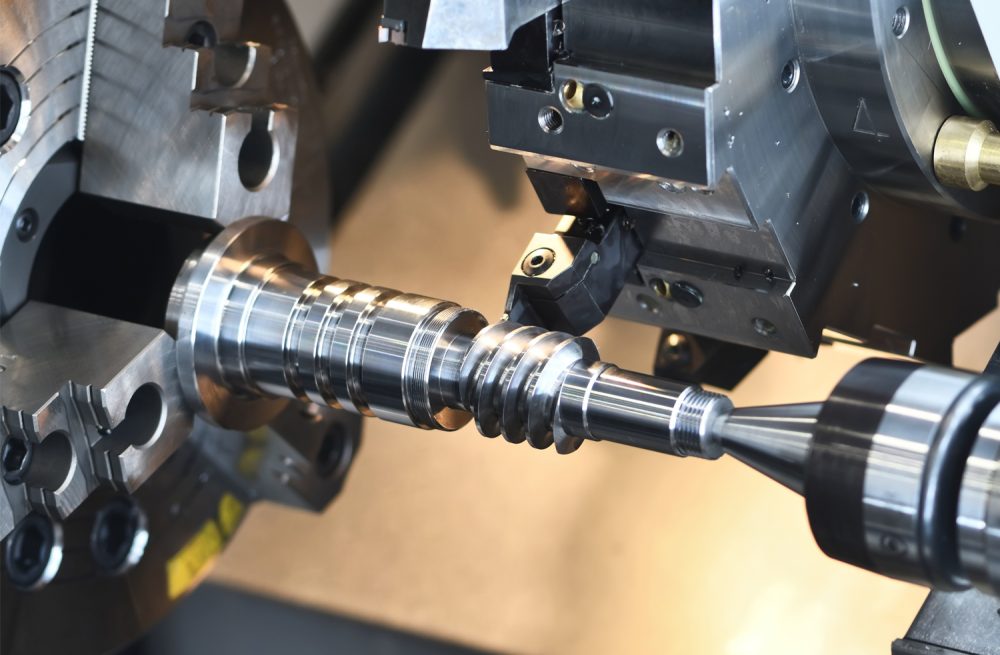

For rotational components, our Haas ST-10, ST-20, and SL-10 CNC lathes are indispensable . These machines are equipped with live tooling and Y-axis capabilities, allowing us to perform multiple operations like turning, milling, and drilling in a single setup. This “done-in-one” approach is crucial for producing parts like MIL-SPEC fasteners with exceptional accuracy and concentricity, as it eliminates the potential for errors that can occur when moving a part between machines .

High-Throughput Production with Haas CNC Machines

This ecosystem is further enhanced by our high-speed Haas DT-1 Drill & Tap centers. Military assemblies often feature a high volume of threaded holes, and the DT-1’s high-RPM spindle and rapid rigid tapping capabilities allow us to produce these features with incredible speed and efficiency . Finally, every component is verified by our Keyence IM series inspection machine, providing automated, data-driven assurance that every part meets the most stringent military standards .

Here is a look at some of the key equipment we utilize:

- Haas VF-2

- Haas VF-4

- Haas Mini-Mill

- Haas ST-10

- Haas ST-20

- Haas SL-10

- Haas DT-1 Drill & Tap Machine

By integrating this suite of Haas machinery, we have built a robust, reliable, and entirely domestic manufacturing process that delivers the quality and performance our armed forces depend on.