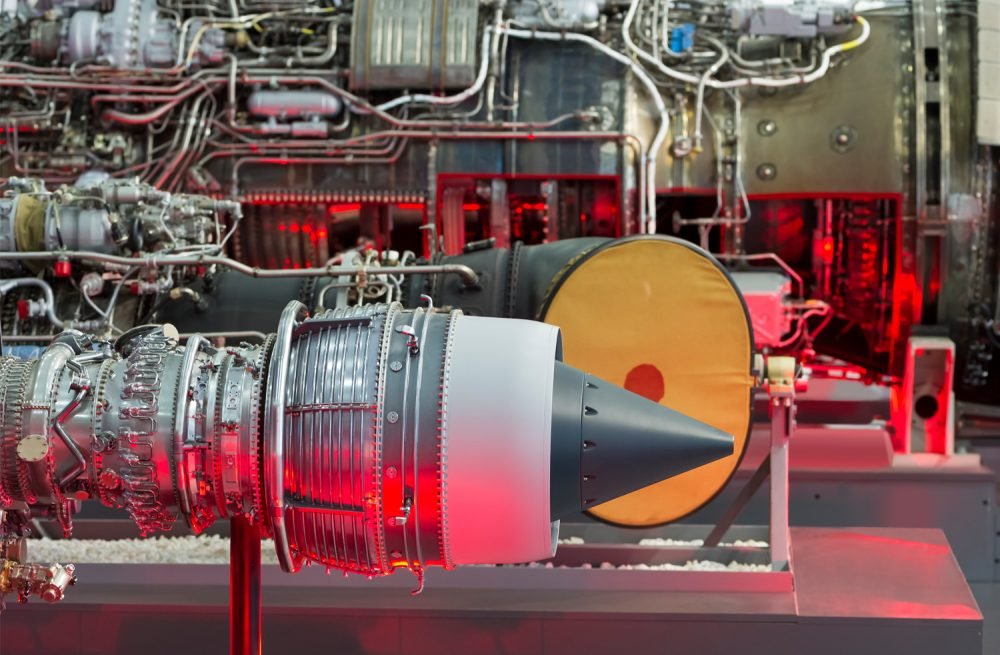

At TEC Aerospace, our manufacturing process for military parts is built upon the use of DFAR compliant materials. This isn’t just a procedural step for us; it is a direct reflection of our role as a responsible partner in the United States Defense Industrial Base.

Understanding DFAR: A Mandate for National Security

The Defense Federal Acquisition Regulation Supplement, or DFAR, is the regulatory framework the Department of Defense (DoD) uses to ensure the quality, security, and integrity of all its acquisitions. The primary objective of these regulations is to procure high-quality supplies and services that support the nation’s defense objectives and enhance mission capability. For every company operating within the defense supply chain, from prime contractors to component manufacturers like us, adherence to DFAR is mandatory. These rules are in place to safeguard national security by maintaining a strong and reliable industrial base, capable of supporting the American warfighter.

A critical part of this framework is the specialty metals mandate. For the critical parts we manufacture, this rule is straightforward: any specialty metals we use, such as high-strength steel, titanium alloys, and nickel-based superalloys, must be melted in the United States or a qualifying allied nation. This requirement is far more than a simple “Made in America” preference. It is a strategic control measure designed to ensure complete traceability and quality from the very beginning of the material’s life cycle. By controlling the origin of these high-performance materials, the regulation ensures that the U.S. and its allies maintain the industrial capacity to produce essential defense hardware.

From Melt to Manufacturing: A Verifiable Chain of Custody

Our strict adherence to this sourcing mandate directly translates to supply chain integrity and risk reduction for our customers. The DFAR requirement for a verified melt source serves as a powerful defense against the infiltration of substandard or counterfeit materials into the supply chain. Every shipment of specialty metal we receive is accompanied by a formal Mill Test Report (MTR), a certificate from the producing mill that attests to the material’s origin and its precise chemical and physical properties. This creates an unbroken and auditable chain of custody from the foundry to our factory floor. This documented traceability ensures that every part we deliver has a verified origin and composition, effectively eliminating materials from unknown or untrusted sources.

Ultimately, our commitment to using only DFAR compliant materials is about reliability. The military systems our components become part of operate in the most demanding environments imaginable, where performance and safety are paramount. By ensuring the certified integrity of our raw materials, we are ensuring the structural integrity and dependable performance of the finished parts we supply. We understand that the quality of our work has a direct impact on mission success and the safety of service members. For that reason, our adherence to these material standards is an integral part of our commitment to delivering components that are unfailingly reliable, because the critical nature of their end-use is always our foremost consideration.

Partner With A Supplier of DFAR Compliant Materials

When mission success depends on component integrity, trust TEC Aerospace. Contact our team to learn how our rigorous compliance standards provide the assurance you need for your critical applications.